Pelton wheel

The Pelton wheel is an impulse turbine which is among the most efficient types of water turbines. It was invented by Lester Allan Pelton in the 1870s. The Pelton wheel extracts energy from the impulse (momentum) of moving water, as opposed to its weight like traditional overshot water wheel. Although many variations of impulse turbines existed prior to Pelton's design, they were less efficient than Pelton's design; the water leaving these wheels typically still had high speed, and carried away much of the energy. Pelton's paddle geometry was designed so that when the rim runs at ½ the speed of the water jet, the water leaves the wheel with very little speed, extracting almost all of its energy, and allowing for a very efficient turbine.

Contents |

History

Function

The water flows along the tangent to the path of the runner. Nozzles direct forceful streams of water against a series of spoon-shaped buckets mounted around the edge of a wheel. As water flows into the bucket, the direction of the water velocity changes to follow the contour of the bucket. When the water-jet contacts the bucket, the water exerts pressure on the bucket and the water is decelerated as it does a "u-turn" and flows out the other side of the bucket at low velocity. In the process, the water's momentum is transferred to the turbine. This "impulse" does work on the turbine. For maximum power and efficiency, the turbine system is designed such that the water-jet velocity is twice the velocity of the bucket. A very small percentage of the water's original kinetic energy will still remain in the water; however, this allows the bucket to be emptied at the same rate it is filled, (see conservation of mass), thus allowing the water flow to continue uninterrupted. Often two buckets are mounted side-by-side, thus splitting the water jet in half (see photo). This balances the side-load forces on the wheel, and helps to ensure smooth, efficient momentum transfer of the fluid jet to the turbine wheel.

Because water and most liquids are nearly incompressible, almost all of the available energy is extracted in the first stage of the hydraulic turbine. Therefore, Pelton wheels have only one turbine stage, unlike gas turbines that operate with compressible fluid.

Applications

Pelton wheels are the preferred turbine for hydro-power, when the available water source has relatively high hydraulic head at low flow rates. Pelton wheels are made in all sizes. There exist multi-ton Pelton wheels mounted on vertical oil pad bearings in hydroelectric plants. The largest units can be up to 200 megawatts. The smallest Pelton wheels are only a few inches across, and can be used to tap power from mountain streams having flows of a few gallons per minute. Some of these systems utilize household plumbing fixtures for water delivery. These small units are recommended for use with thirty meters or more of head, in order to generate significant power levels. Depending on water flow and design, Pelton wheels operate best with heads from 15 meters to 1,800 meters, although there is no theoretical limit.

The Pelton wheel is most efficient in high head applications (see the "Design Rules" section). Thus, more power can be extracted from a water source with high-pressure and low-flow than from a source with low-pressure and high-flow, even though the two flows theoretically contain the same power. Also a comparable amount of pipe material is required for each of the two sources, one requiring a long thin pipe, and the other a short wide pipe.

Design rules

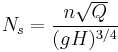

Specific speed

The specific speed  of a turbine dictates the turbine's shape in a way that is not related to its size. This allows a new turbine design to be scaled from an existing design of known performance. The specific speed is also the main criterion for matching a specific hydro-electric site with the correct turbine type.

of a turbine dictates the turbine's shape in a way that is not related to its size. This allows a new turbine design to be scaled from an existing design of known performance. The specific speed is also the main criterion for matching a specific hydro-electric site with the correct turbine type.

The formula suggests that the Pelton turbine is most suitable for applications with relatively high hydraulic head H, due to the 5/4 exponent being greater than unity, and given the characteristically low specific speed of the Pelton.[1]

Turbine physics and derivation

Energy and initial jet velocity

In the ideal (frictionless) case, all of the hydraulic potential energy (Ep = mgh) is converted into kinetic energy (Ek = mv2/2) (see Bernoulli's principle). Equating these two equations and solving for the initial jet velocity (Vi) indicates that the theoretical (maximum) jet velocity is Vi = √(2gh) . For simplicity, assume that all of the velocity vectors are parallel to each other. Defining the velocity of the wheel runner as: (u), then as the jet approaches the runner, the initial jet velocity relative to the runner is: (Vi − u).[1]

Final jet velocity

Assuming that the jet velocity is higher than the runner velocity, if the water is not to become backed-up in runner, then due to conservation of mass, the mass entering the runner must equal the mass leaving the runner. The fluid is assumed to be incompressible (an accurate assumption for most liquids). Also it is assumed that the cross-sectional area of the jet is constant. The jet speed remains constant relative to the runner. So as the jet recedes from the runner, the jet velocity relative to the runner is: −(Vi − u) = −Vi + u. In the standard reference frame (relative to the earth), the final velocity is then: Vf = (−Vi + u) + u = −Vi + 2u.

Optimal wheel speed

We know that the ideal runner speed will cause all of the kinetic energy in the jet to be transferred to the wheel. In this case the final jet velocity must be zero. If we let −Vi + 2u = 0, then the optimal runner speed will be u = Vi /2, or half the initial jet velocity.

Torque

By newton's second and third laws, the force F imposed by the jet on the runner is equal but opposite to the rate of momentum change of the fluid, so:

- F = −m( Vf − Vi) = −ρQ[(−Vi + 2u) − Vi] = −ρQ(−2Vi + 2u) = 2ρQ(Vi − u)

where (ρ) is the density and (Q) is the volume rate of flow of fluid. If (D) is the wheel diameter, the torque on the runner is: T = F(D/2) = ρQD(Vi − u). The torque is at a maximum when the runner is stopped (i.e. when u = 0, T = ρQDVi ). When the speed of the runner is equal to the initial jet velocity, the torque is zero (i.e. when u = Vi, then T = 0). On a plot of torque versus runner speed, the torque curve is straight between these two points, (0, pQDVi) and (Vi, 0).[1]

Power

The power P = Fu = Tω, where ω is the angular velocity of the wheel. Substituting for F, we have P = 2ρQ(Vi − u)u. To find the runner speed at maximum power, take the derivative of P with respect to u and set it equal to zero, [dP/du = 2ρQ(Vi − 2u)]. Maximum power occurs when u = Vi /2. Pmax = ρQVi2/2. Substituting the initial jet power Vi = √(2gh), this simplifies to Pmax = ρghQ. This quantity exactly equals the kinetic power of the jet, so in this ideal case, the efficiency is 100%, since all the energy in the jet is converted to shaft output.[1]

Efficiency

A wheel power divided by the initial jet power, is the turbine efficiency, η = 4u(Vi − u)/Vi2. It is zero for u = 0 and for u = Vi. As the equations indicate, when a real Pelton wheel is working close to maximum efficiency, the fluid flows off the wheel with very little residual velocity.[1] Apparently, this basic theory does not suggest that efficiency will vary with hydraulic head, and further theory is required to show this. There are four type of efficiency in pelton turbine: 1. Hydraulic Efficiency. 2. Mechanical Efficiency. 3. Volumetric Efficiency. 4. Overall Efficiency.

Examples and design data

A working Pelton wheel was used to generate electricity in Southern California. The system had the following specifications. Pitch diameter, 162 inches (13.5 ft; 4.11 m); operating speed, 250 rpm (26.2 rad/s); head, 2200 ft (671 m). The theoretical jet velocity Vi = √(2gh), is calculated to be 376 ft/s (115 m/s), and the wheel edge speed u = 176.7 ft/s (53.9 m/s). Because u ≈ Vi/2, this data is consistent with the theoretical model. The ratio of the runner velocity u to the ideal jet velocity √(2gh) is usually denoted φ. As the theoretical model suggests, for a Pelton wheel working at maximum efficiency, φ is about 1/2. This wheel is estimated to have produced about 60,000 hp (45 MW) on a flow of about 7 m3/s.[1]

System components

The conduit bringing high-pressure water to the impulse wheel is called the "penstock". Originally the penstock was the name of the valve, but the term has been extended to include all of the fluid supply hydraulics. Penstock is now used as a general term for a water passage and control that is under pressure, whether it supplies an impulse turbine or not.[1]

See also

References

External links

|

|||||